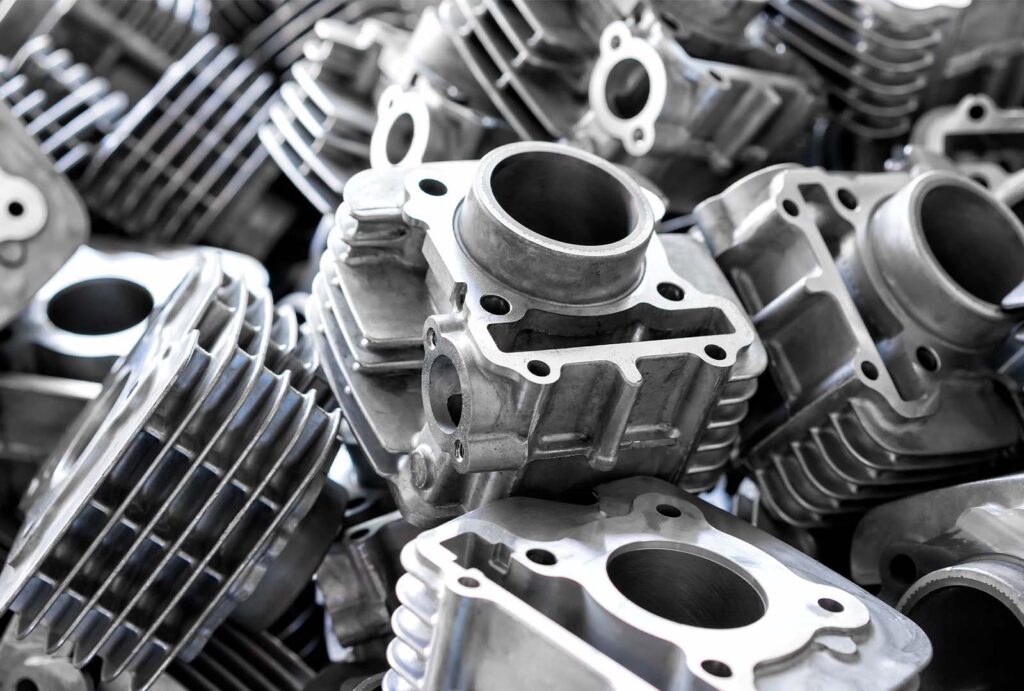

Diecasting, a method of manufacturing that involves putting the molten metal in a mold at high pressure, is now a major aspect of Malaysia’s manufacturing landscape. The process is known for creating complicated metal components that have great precision and superior finish, diecasting can be found in numerous applications such as electronics, automotive as well as consumer goods. In the past, Malaysia has emerged as an important actor in the world diecasting market, due to its high-tech capabilities along with a skilled workforce as well as economically sound policies. This article examines the development of the industry, its current status, and the future of the industry of diecasting in Malaysia.

Diecasting in Malaysia is rooted in the early industrialization process in the late 20th century. At first, the business was focused on the production of basic components to be used in domestic production. But as the economy of Malaysia expanded and diversified it was also able to expand the capabilities of its customers. Nowadays, Malaysian diecasters manufacture a variety of items including automotive components and electronic housings, to complex components of consumer goods. This change was fueled by massive investments in the latest equipment and cutting-edge manufacturing processes. In the end, Malaysia has established itself as an important hub for diecasting products that comply with the international specifications.

The technological advancements been a major factor in the growth of Malaysia’s diecasting manufacturing. Modern machines for diecasting, that are outfitted with highly sophisticated control systems, provide high-quality and efficient manufacturing. Technology advancements like computer-aided designing (CAD) and computer-aided production (CAM) have changed the process by which diecast parts are created and manufactured. These tools allow for the development extremely precise and detailed components, decrease material waste as well as speed up the production process. In the industry, the shift to light and robust components, like magnesium and aluminum alloys is further enhancing the durability and performance of products made from diecast. The advancements in technology have created Malaysian diecasters a major player in the world market.

The high-quality workforce in Malaysia is a further element that is a key to the success of its diecasting business. Malaysian employees are known for their technical knowledge and dedication to maintaining the highest levels of high-quality. The educational institutions and the specific training programs have been essential in creating an array of skilled workers which is able to meet the changing industry demands. Professional development continues to ensure that employees are aware of cutting-edge technologies and methods which allows them to create parts that are in line with international specifications. The emphasis on developing skills has helped to establish Malaysia’s status as a trusted manufacturer of high-quality, precision-engineered components.

In the near future, the outlook of the industry of Metal polishing Malaysia is looking promising. Diecasting demand worldwide for products is anticipated to rise due to the auto electronic, aerospace and consumer goods sector. Malaysia’s location in the middle of Asia, along with its strong infrastructure, and a favorable business climate make it a popular location for investments in diecasting. Additionally, the business is increasingly moving towards the concept of sustainability. Malaysian diecasters have adopted environmentally friendly practices like recycling and using energy efficient production methods. They are not only reducing their environmental impact, but they also go along with the global trend towards environmentally sustainable manufacturing.

Diecasting in Malaysia is evolving from modest beginnings into one of the mainstays of Malaysia’s manufacturing industry. Technology advancements, a highly well-educated workforce and favorable government policies have played a role in this development. With the demand worldwide for precision metal parts is increasing, Malaysia is well-positioned to profit from the opportunities. Through embracing sustainability and innovation and embracing sustainability, the Malaysian diecasting industry will be able to maintain its edge in the market and keep driving the economy. Diecasting’s future in Malaysia is promising, and offers plenty of opportunities to expand as well as success on the global market.