Diecasting has become an essential industry in the manufacturing sector of Malaysia, supplying quality metal components that can be used in various uses. This process involves injecting the molten metal in molds at extreme pressure. This allows for the production of intricate parts that have exceptional precision as well as strength. Malaysia is now the regional leading expert in this area that supports industries like electronics, automobiles, and consumer products. Diecasting firms in Malaysia are steadily increasing their capacities by implementing cutting-edge technologies and techniques to satisfy the growing demand for high-quality metal parts, both in local and international markets.

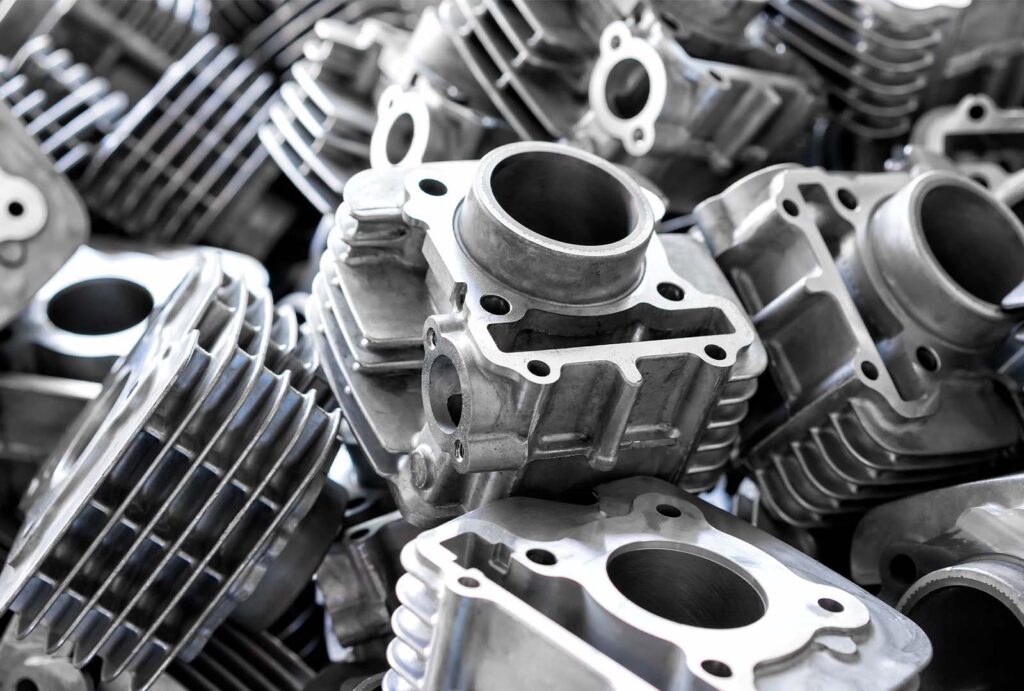

The automobile industry is among major drivers behind demand for diecast parts in Malaysia. Since automakers are trying to improve efficiency in fuel consumption and lessen the weight of cars overall Diecast components made of substances like aluminum or magnesium are increasingly in demand. They are not just light but are also sturdy and tough, making the perfect automotive component including engines, transmission cases and other structural components. Diecasting in the Malaysian diecasting industry has an important role in meeting the demands for the automotive industry by making high-quality parts that improve the performance of vehicles while also ensuring the safety of your vehicle and durability.

Apart from the automobile sector, the diecasting business in Malaysia can also serve the growing electronic and telecoms industries. Its ability to create smaller, complex metal components that have tight tolerances is crucial for these sectors, as accuracy is essential. Diecast components are extensively employed in various products, like laptops, mobile phones and other communication devices where quality and durability are vital. Malaysian companies that diecast have invested in modern equipment and techniques to ensure that they meet the highest specifications required by the electronics sector, positioning Malaysia as a major participant in the electronics component supply chain.

One of the most notable advantages for the industry of diecasting in Malaysia is the adoption of modern manufacturing techniques. Numerous companies within the industry are embracing automation and using computers-aided design (CAD) as well as computer-aided manufacturing (CAM) methods to improve the process of production. The technology can provide greater precision in the design of molds and production times that are faster and a better quality control. Automation helps to reduce labour cost and eliminate wasted materials, enhancing the efficacy of manufacturing. In the end, Malaysian diecasting businesses have the ability to compete successfully globally and offer high-quality goods with competitive costs.

Sustainability is becoming an increasing priority for the Zinc plating Malaysia as concern about environmental effects grow. Diecasting is an extremely effective process because the materials used in diecasting for diecasting, including zinc, aluminum, and magnesium, are able to be used repeatedly, and without losing their qualities. Numerous diecasting firms within Malaysia have adopted recycling initiatives as well as energy efficient production techniques to minimize waste and reduce the carbon footprint of their operations. This sustainability-focused approach does more than protect the environment, but it can also attract environmentally-conscious consumers who want eco-friendly manufacturing methods. Since sustainability is becoming a more prominent industry-wide priority and in Malaysia, the diecasting industry is evolving to meet the demands of these industries.

Despite the many advantages the diecasting industry is in Malaysia is facing a variety of obstacles. One of the biggest concerns is the fluctuating costs of basic material. Metals’ prices, like zinc and aluminum are affected by international market dynamics which means that sudden price hikes will put pressure on the manufacturers profits. Furthermore, as sectors like electronics and automotive are constantly evolving in the coming years, companies who diecast need to stay ahead of the curve by making investments in development and research so that they can adapt to the requirements of their customers. Maintaining an experienced workforce is essential, since the process of diecasting requires specialist expertise in fields like the design of molds, metalurgical and control of quality.

Diecasting, in the end, is Malaysia is a major contribution to the manufacturing sector. It supports sectors that range from automobiles to electronic. The high-quality and long-lasting capabilities that diecasting provides have become a preferred method in the production of metal components as well as Malaysian businesses have taken on the latest technology and sustainable practices to remain ahead of the competition in global markets. With the demand for top-quality sustainable, eco-friendly products rises the diecasting industry in Malaysia has a strong foundation for its continued growth. But, it has to be capable of adjusting to the challenges of material costs changes and the necessity for continuous development. Through a dedication to quality and productivity, diecasting is expected to remain a crucial element of Malaysia’s manufacturing scene for many years to come.